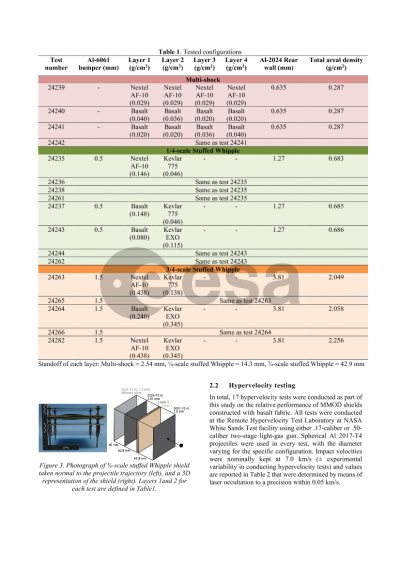

Document details

Abstract

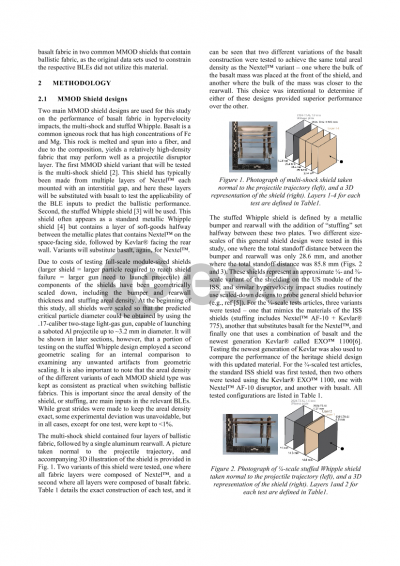

Fabrics have been an integral part of a variety of micrometeoroid and orbital debris (MMOD) shields for over three decades. Their tunable material properties offer targeted enhancements to shielding functions, such as using the relatively high-density ceramic fibers of Nextel™ to increase shock pressures generated in an impact, in comparison to lower density aluminum. However, there may be other fabrics (and/or combinations of fabrics) that exhibit better performance for the same equivalent total areal density. To this end, this paper will present a testing campaign to explore the relative performance of basalt fabric in substitution for Nextel™ in two common MMOD shields, the Stuffed Whipple (Christiansen et al., 1995), and the multishock (Cour-Palais and Crews, 1990). Basalt fabric is manufactured using basaltic glass (high Fe and Mg volcanic rock), which lends to a high fiber-density, similar to the ceramic Nextel™ fibers.

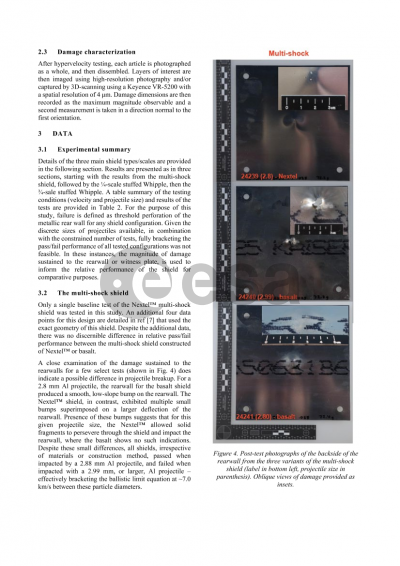

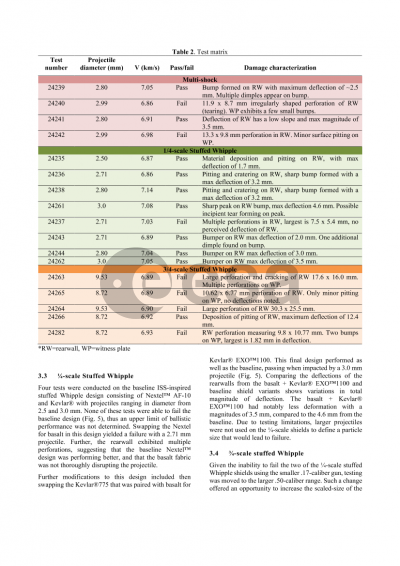

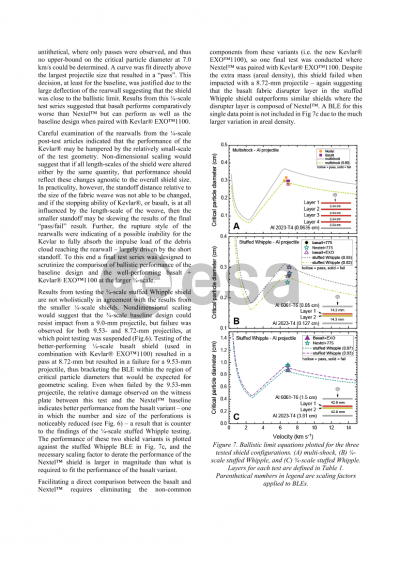

A total of 10 hypervelocity tests have been completed to date in collaboration with the Remote Hypervelocity Test Laboratory located at the NASA White Sands Test Facility using the 0.17-caliber two-stage light-gas gun. Aluminum projectiles were launched nominally at 7 km/s and impacted at a normal incidence angle. Given the cost savings concomitant with this smaller range, the test articles were dimensionally scaled so that shield failure was achievable given the constraints of the launch package size. All elements of the stuffed Whipple shields were thus scaled to 25% of the shields on the US modules of the ISS (i.e., Christiansen et al., 2023). Tested variants included a baseline stuffed Whipple with Nextel™+Kevlar® 775, a version with an equivalent areal density of basalt substituted for Nextel™, and a final configuration with basalt+Kevlar® EXO 1100. In addition, a baseline four-layer Nextel™ multishock, sized appropriately for the 0.17-cal, was compared to four-layer basalt multishock.

Shield performance was based on either perforation of rearwall, or in the case of comparing passes, through the measured deflection of the rear wall bulge. For the stuffed Whipple, the basalt+Kevlar® 775 variant performed marginally worse than the baseline Nextel™+Kevlar® 775 design, but the variant with the basalt+Kevlar® EXO performed better than the baseline. For the multishock shield, the basalt variant had a larger deflection of the rear wall than the baseline all-Nextel™ design when impacted with the same projectile diameter. Given the relative scale of these tests, however, there remains two open questions that will be addressed in the paper. First, it may be possible that the limited standoff available in the ¼-scale stuffed Whipple shield could prematurely drive a shield failure by inhibiting the Kevlar® to fully capture the momentum of the debris cloud before it is transferred to the rear wall. Second, the differences in particle size that would lead to either a failure or pass of the different shield configurations would also be scaled, and a comparative analysis of the relevant particle diameters leading to each result could be within the increments of available projectile sizes – thus inhibiting a detailed comparison. To address these potential matters, four additional full-scale tests will be conducted on the stuffed Whipple shield for consideration in the final paper.

Preview