Document details

Abstract

In the framework of the ESA CleanSat programme Cranfield University is developing a family of drag augmentation system (DAS) modules to enable small satellites in Low Earth Orbit (LEO) to comply with space debris mitigation requirements. The disposal manoeuvre approach selected, allowing a clearance time within the 25 years after EoM, is augmenting the spacecraft orbital decay by deploying a device so that the remaining orbital lifetime is compliant (ISO 24113).

There are currently two mature Cranfield DAS designs (one with flight heritage) based on deployable Kapton sails using stored energy for deployment.

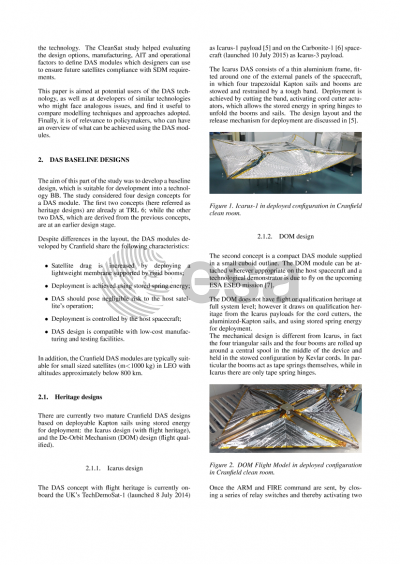

The DAS concept with flight heritage is currently on-board the UK’s TechDemoSat-1 (launched 8 July 2014) and Carbonite-1 spacecraft (launched 10 July 2015). This consists of a thin frame, fitted around one of the external panels of the spacecraft, in which the lightweight sails and booms are stowed and restrained by a tough band. Deployment is achieved by cutting the band, which allows the stored energy in spring hinges to unfold the booms and sails.

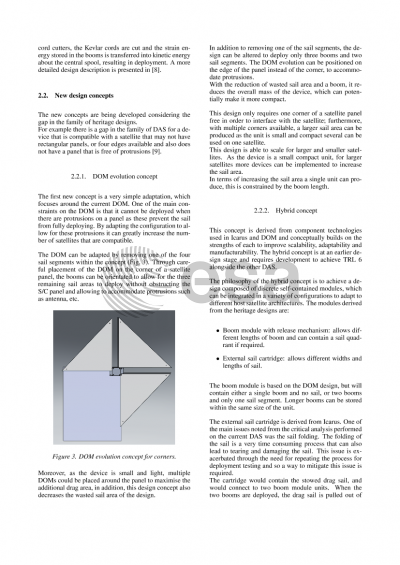

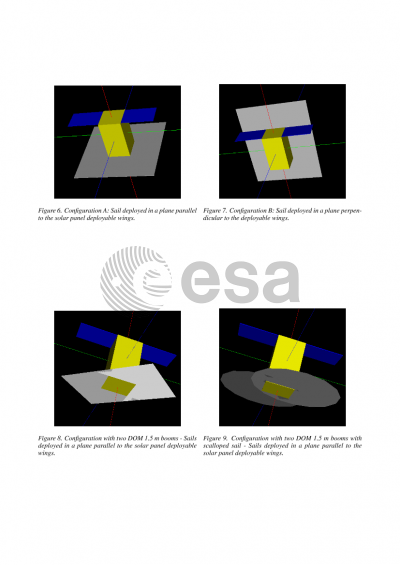

The second concept is a compact DAS module supplied in a small cuboid outline. The de-orbit mechanism (DOM) module can be attached wherever appropriate on the host spacecraft and a technological demonstrator is due to fly on the upcoming ESA ESEO mission.

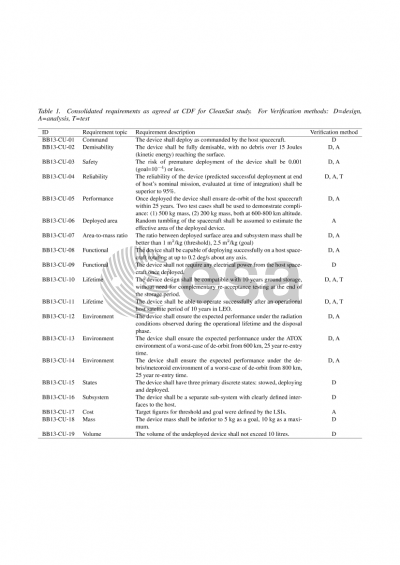

The key drivers used during the design process were: low cost (use of COTS, avoidance of complex systems), low mass, easy testability, safety (avoiding risk of premature deployment), reliability (ensuring the proper function of the device), and avoidance of additional debris production. These drivers matched with top-level requirements, from a potential customer’s perspective (e.g.: satellite integrators), which were defined during the CleanSat study. Other relevant requirements for the DAS included demisability, performance (in terms of orbital decay), area-to-mass ratio, functionality, lifetime (on ground and on orbit), and environment compatibility.

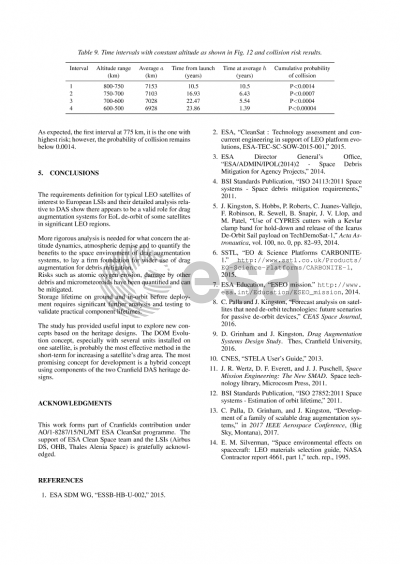

This paper discusses the compliance of the Cranfield DAS designs with the identified requirements, and illustrates the scalability via application to several case study missions (500 kg and 200 kg LEO satellites).

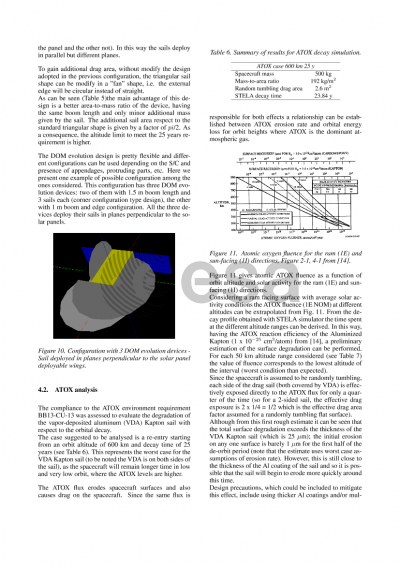

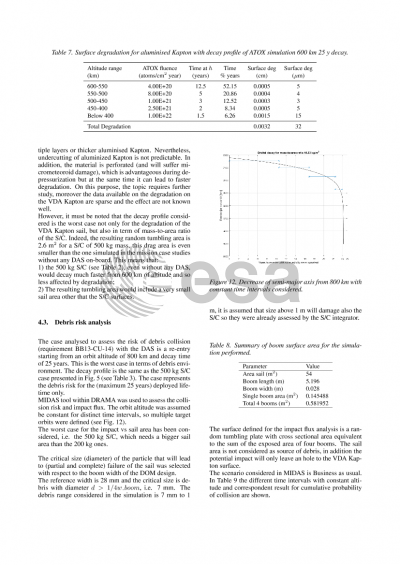

The two most challenging aspects to assess were compliance with the lifetime required for storage on ground and pre-deployment storage on orbit, and the effect of the orbital environment (radiation, ATOX, debris) on the sail.

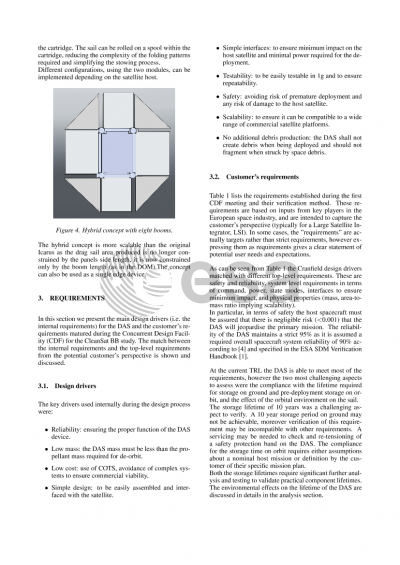

The study has provided useful input to explore new concepts based on the heritage designs; these concepts are evolutions of the DOM unit and hybrid designs. The hybrid design combines aspects of the Icarus and the DOM concepts to reduce the limitations of the respective individual devices and improve scalability, adaptability and manufacturability.

In addition, this work is helping to achieve commercial readiness for the technology and to evaluate design options, manufacturing, AIT and operational factors. This will enable development of a commercial DAS offering that will be an attractive solution for small satellite integrators, allowing them to meet debris mitigation requirements.

This paper is aimed at potential users of the technology, as well as at developers of similar technologies who might face analogous issues, and find it useful to compare modelling techniques and approaches adopted. Finally, it is of relevance to policymakers, who can have an overview of what can be achieved using the DAS modules.

Preview