Document details

Abstract

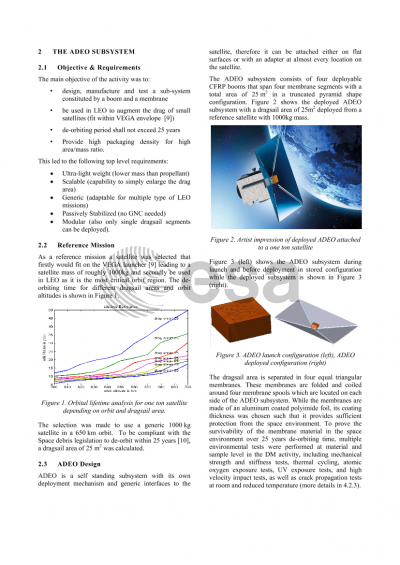

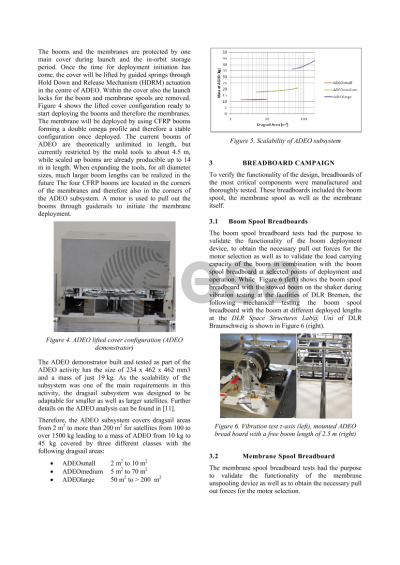

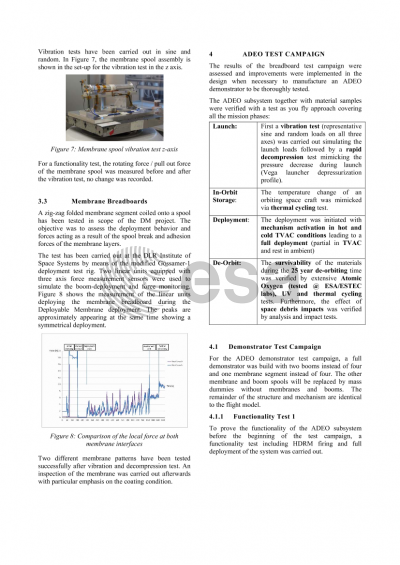

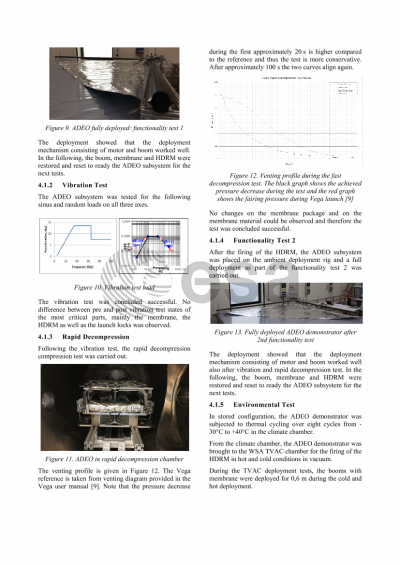

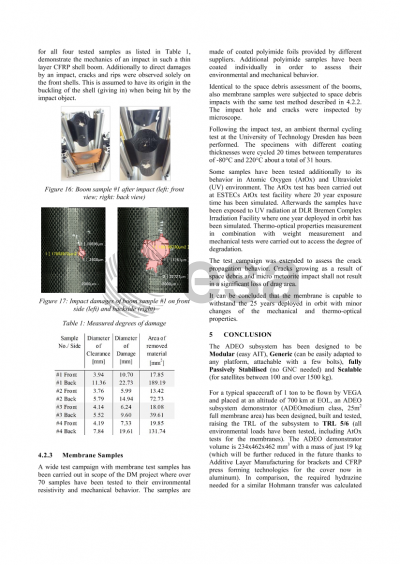

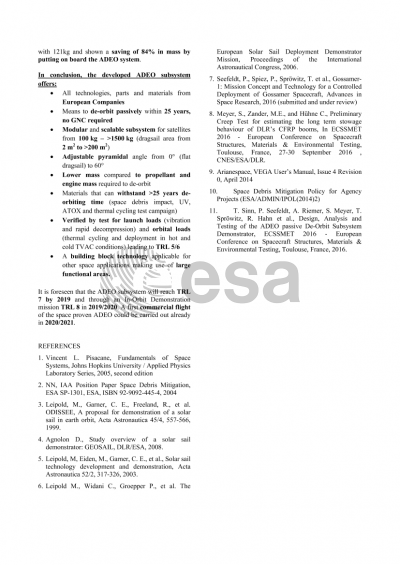

The space debris environment, especially in low earth orbit, is an increasing risk for all spaceflight missions. Without effective mitigation measures the debris density will increase to a level where spaceflight becomes more and more endangered. Therefore, to ensure safety for future space flight, end-of-life de-orbiting of satellites and upper stages is required by the respective standards. Deployable gossamer structures for drag sails might offer a passive de-orbit solution. The paper at hand outlines the development of such a system applicable for LEO satellites between 100 kg to 1000kg. It is based on the Gossamer-1 technology of the German Aerospace Center (DLR). Further developments are pursued in the ESA projects “Deployable Membrane” (DM) and “Architectural Design and Testing of a De-orbiting Subsystem” (ADEO). The ADEO subsystem is a scalable drag augmentation device that uses the residual Earth atmosphere present in low Earth orbit. For initiation of the de-orbit maneuver a large surface is deployed (developed and tested in the DM activity) which multiplies the drag effective surface of the satellite. Thereby the drag force is increased as well causing accelerated decay in orbit altitude. Advantageous about a drag augmentation device is that it does not require any active steering and can be designed for passive attitude stabilization thereby making it applicable for non-operational, tumbling spacecraft as well. The ADEO subsystem consists of four deployable CFRP booms that span four sail segments with a total area of 25 m2 in a truncated pyramid shape configuration. While the sails are made of an aluminum coated polyimide foil, its coating thickness was chosen such that it provides sufficient protection from the space environment. To prove the survivability of the sail material in the space environment over 25 years de-orbiting time, multiple environmental tests were performed at material and sample level in the DM activity, including mechanical strength and stiffness tests, thermal cycling, atomic oxygen exposure tests, UV exposure tests, and high velocity impact tests, as well as crack propagation tests at room and reduced temperature. Currently a fully functional full scale demonstrator with one sail and two booms is being subjected to environmental testing including deployment testing in thermal-vacuum environment and ambient conditions. An overview of the design, the results of the breadboard test campaign as well as the extensive demonstrator test campaign will be the main body of this paper. The paper will conclude with a development plan leading to a future in orbit demonstration of this passive de-orbit subsystem.

Preview